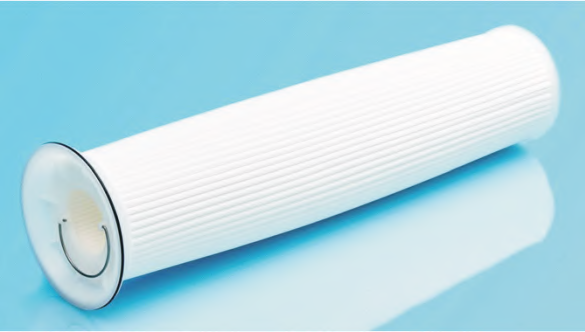

Rocket Bag Type Filter Cartridge

RPO / RPE/ RPG series / PLEATED FILTER ELEMENT

Rocket pleated bag type filter cartridge is a new innovative product, and a great alternative to standard filter bags. Using a unique pleating structure, Rocket provides up to four times the filter area compared to standard filter bag.

Application

- Automotive degreasing and washing fluids.

- Steel emulsions and bath filtration.

- Process cooling water.

- Membrane pre-filtration.

- Granular cooling fluids.

- Coal-water slurry.

- Desalination processes.

- Machinery cutting fluids and many more.

- Unique pleated structure provides up to four times the filter area than common.

- Available as absolute (four-layer melt-blown filter material) with efficiencies up to 99.9% and nominal (two-layer needle felt filter material) rated filter bags.

- Conical cap seal.

- Filts into standard restrainer baskets.

- Rocket bag type filter cartridge range.

- Unique pleated structure provides up to four times the filter area than common

- Available as absolute (four-layer melt-blown filter material) with efficencies up to 99.9% and nominal (two-layer needle felt filter material) rated filter bags.

- Conical cap seal

- Fits into standard restrainer baskets.

- Reduces maintenance costs due to longer lifetime.

- Material is free from creater forming substances (such as silicones etc.)

Filter specifications

Materials

- PO : Polypropylene

- PE : Polyester

- PG :Fiber glass

Seal ring : Beato welded polypropylene/ polyester seal ring

O-rings (option) : NBR, Silicone, EPDM, Viton

Retention ratings – Absolute :

- PO :1,5,10 μm

- PE : 1,5,10,25 μm

- PG : 1,5,10,25 μm

- Nominal :

- PO : 1,5,10,25,50,100,200 μm

- PE : 1,5,10,25,50,100,200 μm

- 01 : 178 x 350 mm

- 02 : 178 x 700 mm

Filter area –

- 01 : 1.1 m²

- 02 : 2.2 m²

- 02 : 3.2 m² (only for fiber glass)

Max. differential pressure²* – 2.5 bar Recommended change-out

pressure drop for disposal³* – 0.8 to 1.5 bar

Maximum operating temperatures

- PO : < 90°C

- PE : < 140°C

- PG : < 90°C

Maximum flow rates³*

- Absolute : Nominal :

- 01 : 25 m³ /h 01 : 30 m³ /h

- 02 : 50 m³ /h 02 : 60 m³ /h

- Seal ring beato welded polypropylene / polyester seal ring

- O-rings (option) : nbr, silicone, epdm, viton

- Retention ratings :

absolute : po : 1,5,10 m pe : 1,5,10,25 m pg : 1,5,10,25 m :

nominal : po : 1,5,10,50,100,200 m pe : 1,5,10,25,50,100,200 m - Dimentions / parameters :

sizes 01 : Ø 178 x 350 mm 02 : Ø 178 x 700 mm

filter area 01 : 1.1 M² ; 02 : 2.2 M² ; 02 : 3.2 M² (only for fiber glass );

max. differential pressure²*2.2 bar - Recommended change-out pressure drop for disposal³* :

…………………………0.8 to 1.5 bar

Maximum operating temperatures :

- po : < 90°C

- pe : < 140°C

- pg : < 90°C

Maximum flow rates 4* :

- Absolute : Nominal :

- 01 : 25 m³ /h 01 : 30 m³ /h

- 02 : 50 m³ /h 02 : 60 m³ /h